Materials such as packaging and documentation costs should be at the barest minimum. The COGS refers to the total money a company spends on labor, materials, and overhead costs related to its production processes or services. Manufacturing costs involved in the COGM include direct labor, factory overhead, and other manufacturing-related expenses. Every entrepreneur, especially those new to the world of business, often hears the term “Cost of Goods Manufactured” (COGM). While it might sound simple, COGM actually plays a very important Certified Bookkeeper role in running a business.

Direct Labor

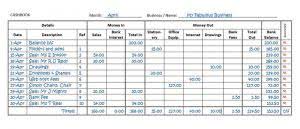

We’ll start with beginning and finishing WIP inventory since it’s unclear what those terms mean at first glance. The cost of goods manufactured formula is often confused with the cost of goods sold formula, but these two formulas differ. With 10 Years of Experience in Sourcing products from china,We will share knowledge of how to wholesale products from china and how different types of products are made in China. Synder matches products by name or SKU, updates quantities, and adjusts COGS accounts.

Example of Cost of Goods Manufactured Calculation

- The cost of goods manufactured (COGM) is an important metric, especially for manufacturing businesses, because it can affect profitability, which is the ultimate goal of any business.

- The cost of goods manufactured is included in a company’s income statement, usually together with the beginning and ending finished goods inventories.

- Mastering COGM goes beyond improving your bottom line–it’s about building a smarter, more resilient business.

- See first-hand how to boost manufacturing efficiency and reduce your cost of goods manufactured with a risk-free two-week trial of Unleashed.

You know, just haggling a bit to get better prices for the materials you need. It’s all about cutting out the waste, like trimming the fat from a steak. Maybe switch to LED lights or something, just to save a bit here and there. Knowing the difference between COGM and COGS helps you manage inventory better and plan for future production needs. It’s all about keeping track of what’s made and what’s sold to keep the business running smoothly. As a side note, before we begin, it’s a good idea to read our post about types of inventory.

Formula for Calculating Cost of Goods Manufactured

It reveals how efficiently your business operates, uncovers opportunities to cut costs, and empowers you to make data-driven decisions that fuel growth. Synder streamlines the process by automating financial data from all your sales channels, ensuring accurate COGS calculations. This allows you to set competitive prices, maintain healthy profit margins, and keep your finances organized effortlessly. If any accrued manufacturing costs haven’t been paid yet but have been incurred during the period, they are credited in this entry. The same applies to WIP inventory, which represents the value of partially completed goods. The journal entry credits WIP inventory to reflect the portion of manufacturing costs that have been added to the work in process.

This formula assumes that you do not have any unsold inventory from the previous month. So, if all raw materials, labor, and overheads have been accounted for in the current period, you can simply use this formula to get the total COGM. Raw material costs are one of the largest components of COGM.

- The COGS refers to the total money a company spends on labor, materials, and overhead costs related to its production processes or services.

- Your profitability depends on identifying all sources of costs, and your inventory is the core part of your costs.

- Basically, it’s all the indirect costs that keep the production wheels turning.

- Robots don’t need breaks or complain about overtime, so they can save you big bucks.

- The one thing that all of these things have in common is that they’re all finite.

- On the other hand, if the selling price is too high, consumers might look for similar products at lower prices.

Let’s talk about how you can calculate the cost of goods manufactured by mentioning an example of a furniture company and its production process. Remember that this is merely an illustration and that the precise COGM costs may change based on the business and the product being produced. The COGM only calculates the cost of goods sold for a certain period. Your profitability depends on identifying all sources of costs, and your inventory is the core part of your costs. You can stay on top of your costs by understanding, measuring, and tracking COGM.

More on manufacturing accounting

The COGM of $30,000 represents the total cost of goods completed and ready to sell during the period. This is key for calculating your cost of goods sold (COGS) and analyzing balance sheet your production efficiency. Reducing labor costs is an excellent way to lower the expense of goods manufactured without compromising product quality. Direct materials refer to all the raw materials used to produce the finished product or in its final form.

Prime cost is the total manufacturing cost excluding the value of direct materials. Prime cost can also be defined as the sum of direct labor costs, factory burden (overhead) and material conversion costs. The COGM schedule is a part of the financial statement of a cost of goods manufactured business that shows the total cost incurred by a company to manufacture goods during a specific period, typically a month or a year. COGM is used in the income statement of the reporting and is subtracted from sales to then calculate gross margin (the portion of a company’s revenue after direct costs have been removed).